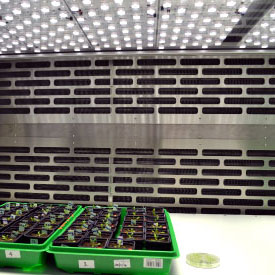

PlantScreen™ data acquisition and control software allows the user to define measurement protocols, and view the current status of the device. Pre-defined protocols are available that may be edited easily by the user. These protocols carry out repeated sequences of measurements under defined environmental conditions. All data are stored into a relational MySQL database, in which it is easy to search data by selected parameters. The number of measurements that may be made depends on the size of storage space. It is possible to record up to 1000 measurements on a 200 gigabytes storage device.

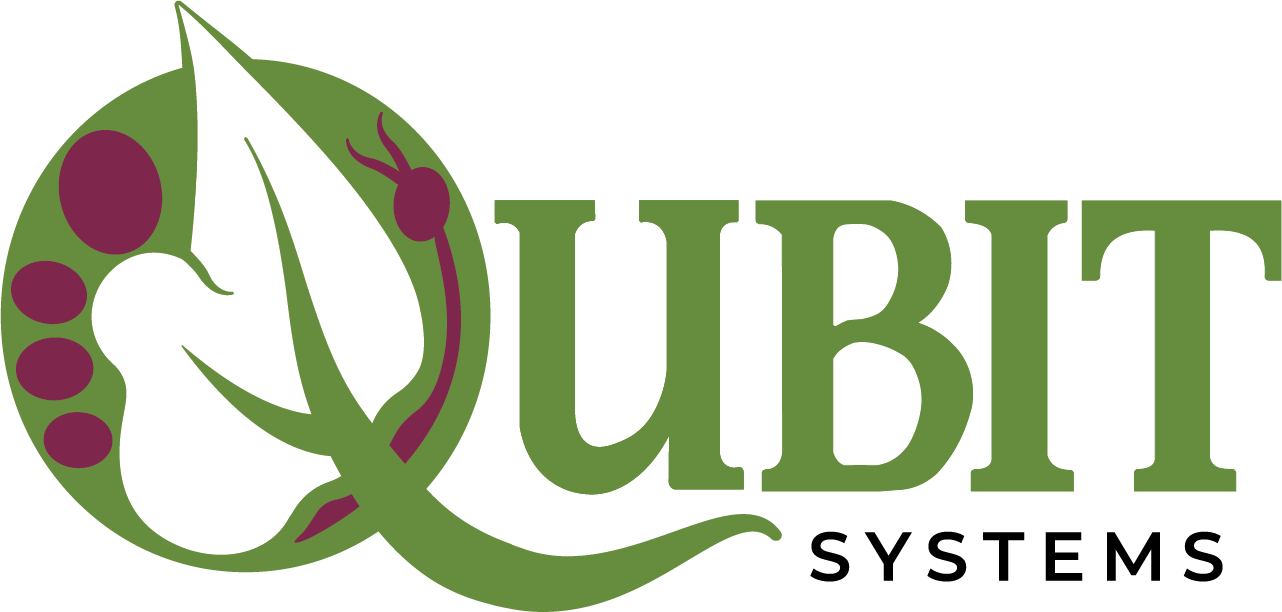

PlantScreen™ Client software controls and monitors the entire PlantScreen™ device via a touch screen interface.

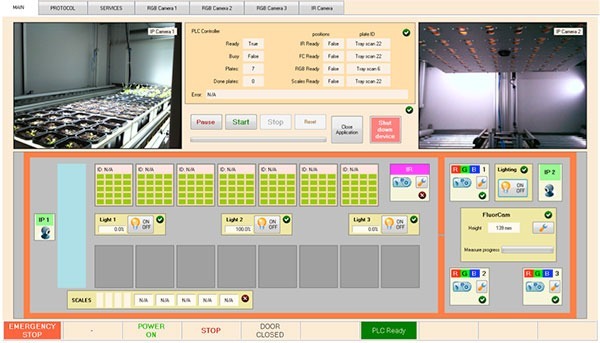

The touch screen is divided into several operational areas, including a schematic representation of the entire device which displays the number of trays inserted into the PlantScreen™, light levels and status of individual measurement devices and their activity.

Lighting in the cultivation (non-imaging) section of the chamber is divided into several sectors. In any sector, it is possible to separately switch the lighting on or off and to set the desired irradiance level.

Control allows both manual setting of all parameters and a fully automatic mode that operates in accordance with a predefined protocol. The automated mode may be over-ridden if required.

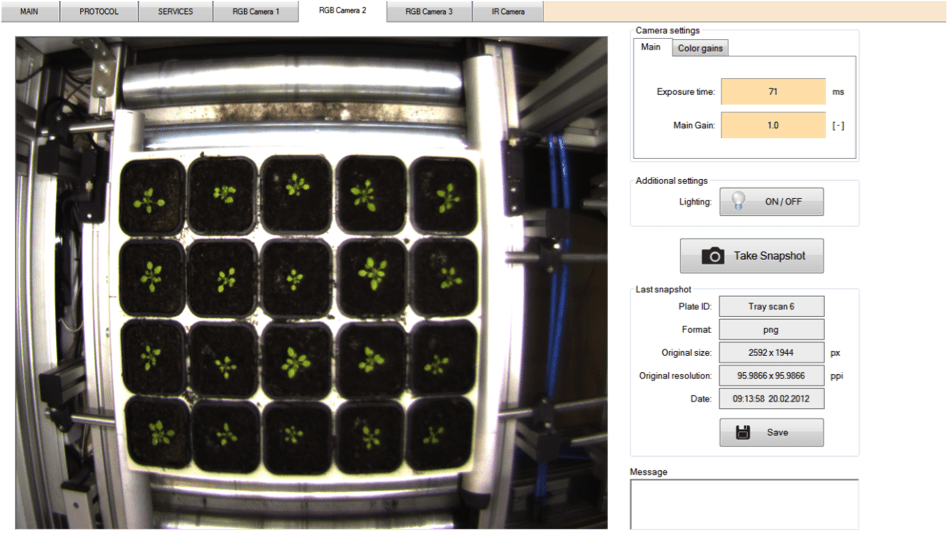

OPERATION OF THE IMAGING STATIONS IS DONE IN SEPARATE SOFTWARE TABS, EACH CAMERA HAVING ITS OWN CONTROL PANEL. HERE, THE USER CAN SET THE CONTROLS FOR EXPOSURE TIME, GAIN, AND BALANCING BETWEEN DIFFERENT COLOR COMPONENTS ETC.

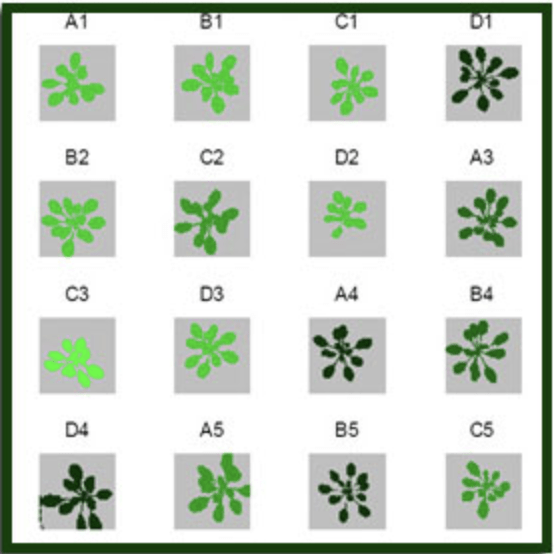

The Take Snapshot button is used for instantaneous image capture. The image is displayed in the left frame, together with details such as resolution, time of the scan, format, etc. The image can be saved using the Save button. For high-quality RGB images, it is possible to turn on illumination lighting using the – On/Off button. In automatic mode, the PlantScreen™ software can be set so that images are automatically recorded and saved into a database for subsequent processing. The system is designed so that lighting conditions, and plant position with respect to cameras, are identical for each image. The IR camera is operated in a similar manner to the RGB camera, under a separate tab. Chlorophyll fluorescence imaging and hyperspectral imaging have more complex control protocols.

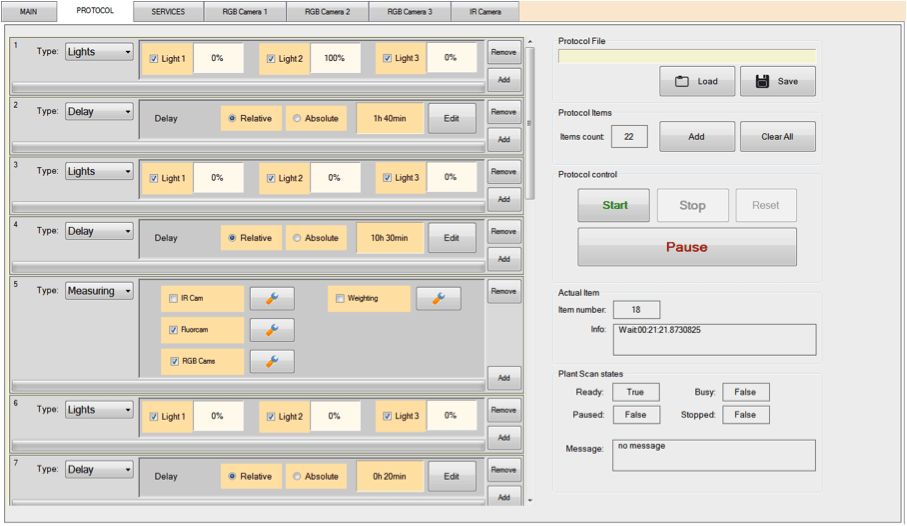

The PlantScreen™ is designed primarily for operation in automatic mode. The user may select a predefined protocol from a Wizard, or enter individual operational steps that can be saved as a new protocol:

- Switching the lighting on / off in the cultivation area

- Scanning using RGB cameras

- Scanning using IR camera

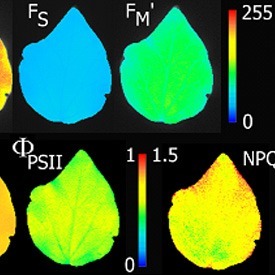

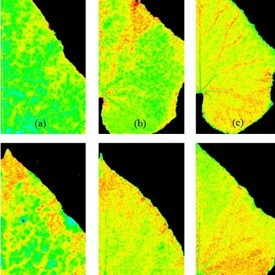

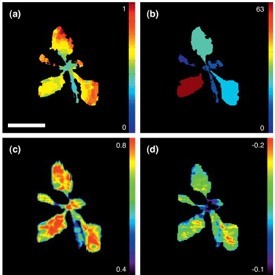

- Implementation of chlorophyll fluorescence measurements under their own measurement protocol

- Implementation of hyperspectral measurements under their own measurement protocol

- Weighing of individual samples

- On the base of weighting, supply a specified level of irrigation and nutrients

Protocols can be started and stopped using the Start button or Stop button. Protocols may be paused using the Pause button. The user can save the developed measurement protocols onto the PlantScreen™ computer or a portable drive.